Some Known Questions About Manufacturing Industries.s

Wiki Article

Our Manufacturing Industries PDFs

Table of ContentsGetting The Additive Manufacturing To WorkLean Manufacturing - An OverviewUnknown Facts About Plastic ManufacturingThe 9-Minute Rule for Hon Hai Precision

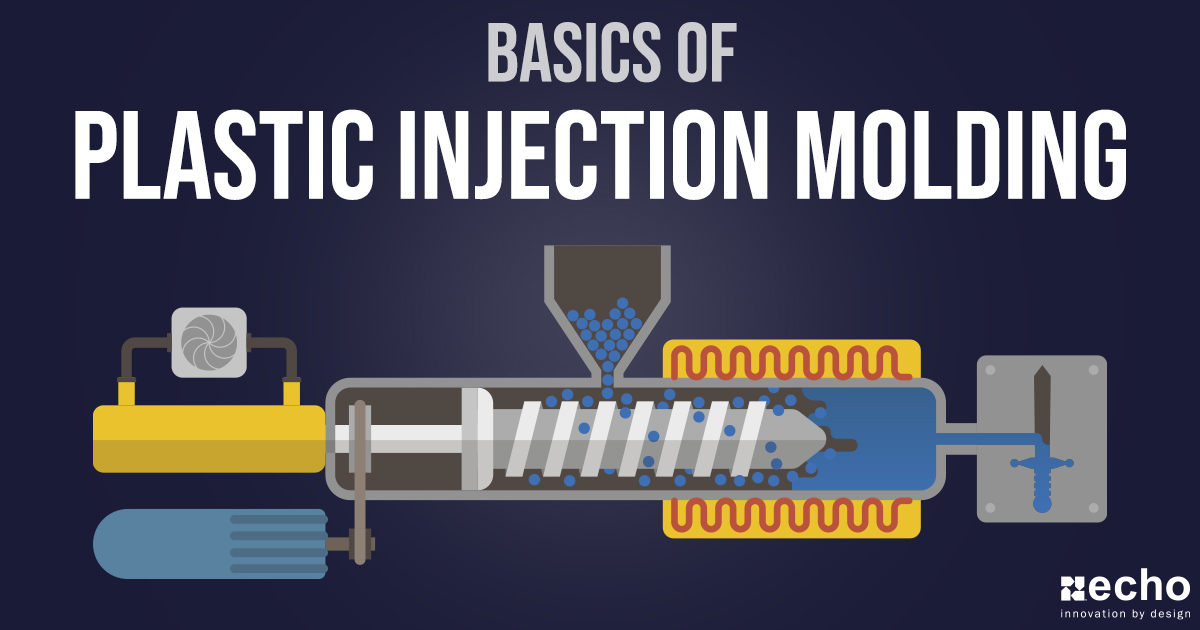

With shot moulding, pre-dried granular plastic is fed by a forced ram from a receptacle right into a heated barrel. As the granules are slowly moved ahead by a screw-type plunger, the plastic is pushed into a heated chamber, where it is melted. As the bettor advancements, the melted plastic is forced through a nozzle that rests versus the mould, allowing it to enter the mould tooth cavity through a gate and runner system.The series of occasions during the shot mould of a plastic part is called the injection moulding cycle. The cycle starts when the mould closes, followed by the shot of the polymer into the mould dental caries. As soon as the tooth cavity is filled, a holding stress is preserved to compensate for product shrinkage.

Once the dental caries is 98% full, the machine switches from speed control to pressure control, where the cavity is "loaded out" at a consistent stress, where adequate velocity to get to preferred pressures is called for. This lets workers regulate part measurements to within thousandths of an inch or far better. Like all industrial procedures, shot molding can produce mistaken parts, also in toys.

Lean Manufacturing - An Overview

Tests are frequently done prior to complete production runs in an effort to forecast defects and also determine the ideal specs to utilize in the shot process.: 180 When loading a brand-new or strange mould for the very first time, where shot dimension for that mould is unidentified, a technician/tool setter may execute a dry run prior to a complete manufacturing run.

Holding stress is boosted up until the parts are without sinks and also component weight has been accomplished. Moulding problems [edit] Injection moulding is a complex modern technology with feasible production problems. They can be created either by defects in the moulds, or extra frequently by the moulding procedure itself.: 4785 Moulding problems Different name Summaries Causes Sore Blistering Increased or split area on surface of the part Device or product is as well warm, usually triggered by a lack of cooling down around the tool or a faulty heating unit.

Plastic Manufacturing - Truths

Installed particulates International particle (burned material or various other) ingrained in the part Particles on the tool surface, infected material or international debris in the barrel, or excessive shear warm burning the product prior to shot. Flow lines Directionally "off tone" wavy lines or patterns Shot rates as well sluggish (the plastic has cooled off way too much during shot, injection rates need to be set as rapid as is appropriate for the procedure and also material used).Filling up also fast, not enabling the sides of the part to establish. Mould might be out of enrollment (when the two halves do not centre properly and part wall surfaces are not the same density). The offered details is the common understanding, Modification: The Absence of pack (not holding) pressure (pack pressure is used to load out despite the fact that is the component throughout the holding time).

In other words, as the part diminishes the material separated from itself as there was not sufficient resin in the tooth cavity. The gap can take place at hop over to here any area or the part is not limited by the thickness but by the resin flow and thermal conductivity, however it is more probable to take place at thicker locations like ribs or employers.

Knit line/ Fuse line/ Transfer line Discoloured line where 2 flow fronts fulfill Mould or worldly temperature levels established also reduced (the material is chilly when they meet, so they don't bond). Time for transition between injection as my response well as transfer (to packing and holding) is prematurely. Turning Altered component Cooling is too short, material is too warm, absence of cooling down around the tool, incorrect water temperatures (the components bow inwards in the direction of the warm side of the tool) Uneven shrinking in between locations of the part.

Everything about Manufacturing

125 inch wall surface density is +/- 0. The power required for this procedure of injection moulding depends on numerous points and also differs in between products utilized. Below is a table from web page 243 of the same referral as previously stated that ideal shows the characteristics pertinent to the power required for the most generally made use of materials.In enhancement to mounting evaluation systems on automated devices, multiple-axis robots can eliminate parts from the mould as well as place them for further navigate to these guys procedures. Specific instances consist of eliminating of components from the mould immediately after the parts are developed, as well as applying device vision systems. A robot grips the part after the ejector pins have been prolonged to free the part from the mould.

Why is injection molding device manufacturing so efficient? What is Injection Molding?

The injection molding maker makes use of personalized mold and mildews to fill them out according to requirements, developing identical copies that can be customized in a selection of ways. What's even more, injection molding is a really versatile process, enabling for a large range of different materials as well as coatings, which makes it a popular choice in numerous industries with entirely various goals as well as requirements - additive manufacturing.

Report this wiki page